Environmental Remediation Experience

Our staff has decades of practical experience with diverse accomplishments based on a commitment to provide contracting services that are consistent, professional and of the highest quality to create value for our clients. The long-term relationships we enjoy with our Clients, large international consulting firms, mid-size regional firms and sole proprietor consultants alike, is a result of our commitment and dedication to their success.

In the following sections, our experience is summarized by Client sectors.

Process Technologies

The staff at X2 Environmental Contracting, INC has decades of practical environmental remediation experience.

We are proficient in all aspects of environmental remediation, implementing proven technologies for:

- Reductive Dechlorination of Halogenated Organic Solvents

- Biodegradation Systems for BTEX, including PHOSter II

- In Situ Chemical Oxidation Injection

- Hydrogen Peroxide

- Potassium Permanganate

- Sodium Persulfate

- pH buffering: Carbon Dioxide and Sodium Hydroxide Injection

- Soil Flushing, Air Stripping, and Vapor Extraction of VOC

- Gas Diffusion Using CO2, H2, N2, N2O, O2, O3, and Alkanes

Contact us to schedule a consultation if you need environmental corrective action contracting services.

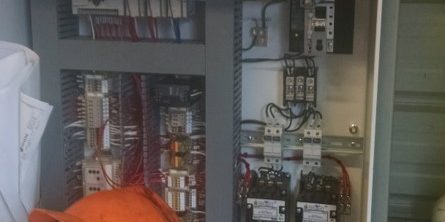

Installation & Construction

Our staff has performed installation of remediation systems on a wide range of sites.

We have the equipment and resources available for turn key installation services, including grading, concrete forming/finishing, piping, electrical, controls, pumps, telemetry, skid systems, housing/canopies, and landscape restoration. We have substantial experience installing and constructing the following systems

- Soil Vapor Extraction

- Gas-Phase Injection

- ISCO Liquid Reagent Injection

- Groundwater Recirculation

- pH Adjustment

- Storm Water Pre-Treatment

- Activated Carbon Filter Vessels

- Air Stripping Towers

- Incineration

Operation & Maintenance

Our full-time field technicians perform system maintenance on a scheduled, routine basis. They average over 15 years experience with system O & M, and are able to quickly understand and adapt to the specific requirements of innovative new technologies.

Our Clients rely on us to keep their remediation projects performing efficiently, and to trouble shoot promptly when necessary.

Our O & M services include

- Compressor servicing

- Pump rebuilding and replacement

- Piping and fittings inspection and repair

- Process tank cleaning

- Valve repair and replacement

- Activated Carbon filter media change out - liquid and vapor phase

- Bag filter maintenance

- Chemical reagent mixing and injection

- gas-phase injection systems

- Instrumentation maintenance

- Sampling equipment maintenance

- Automation repair and modification

Special Support Services

Much of our experience has involved assisting Clients with legacy remediation and industrial process systems. We have provided mechanical, electrical, controls, and automation services on a wide variety of projects and systems.

In addition, we have substantial civil construction experience in the areas of

- earthwork

- concrete

- retaining walls

- underground utility installation

- stormwater control systems

Some of the common problems we have assisted Clients with over the years include

- Process optimization and modification

- Telemetry failures

- Automation integration

- Pumping systems controls and specifications

- Solenoid valve controls and specifications

- Mechanical repairs - welding, fabrication, supports

- Electrical supply sizing, transformer selection and installation